Have you ever wondered about the differences between membrane bioreactors (MBRs) and conventional activated sludge (CAS) systems when it comes to wastewater treatment? Both technologies play essential roles in treating and purifying wastewater, yet they operate in distinctive ways with unique advantages and limitations. By understanding their key differences, you can make informed decisions about which technology is best suited for various situations.

Understanding Wastewater Treatment

Wastewater treatment is a critical process that ensures the safe return of treated water to the environment, preventing pollution and safeguarding public health. Various technologies have been developed to efficiently handle this process, with MBRs and CAS systems being notable examples.

What is Conventional Activated Sludge?

Conventional Activated Sludge (CAS) systems are among the most traditional and widely used methods for treating wastewater. The process involves using microorganisms to break down organic matter present in the water. Air is introduced to the aeration tank, providing the oxygen necessary for the microbes to thrive and consume the organic pollutants.

How Membrane Bioreactors Work

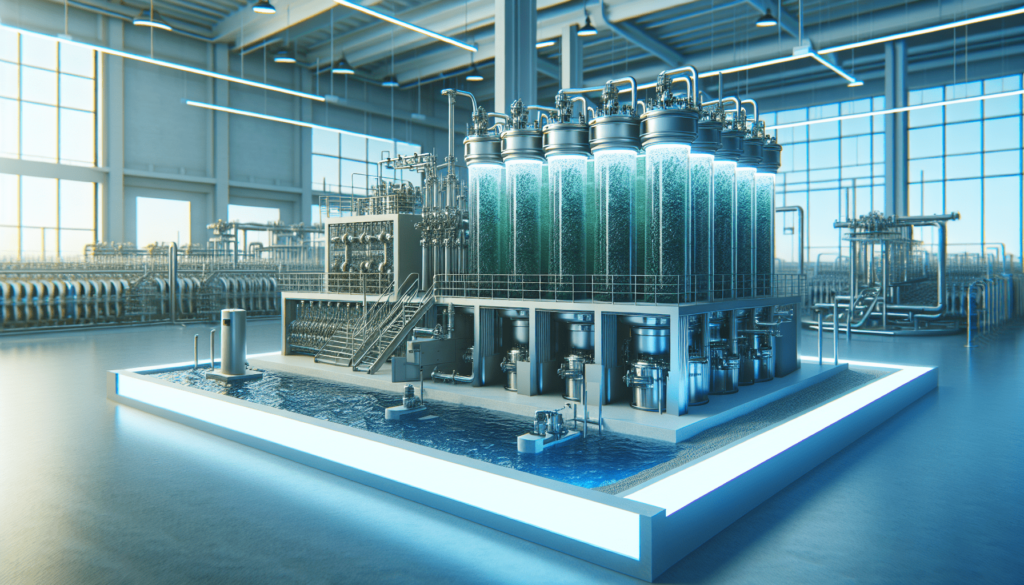

Membrane Bioreactors, or MBRs, combine biological treatment with membrane filtration. The membranes are used to separate the mixed liquor from the treated water, allowing for high-quality effluent and a smaller system footprint. This integration of biological and physical treatment processes results in an efficient and effective way to purify wastewater.

Comparing System Components

Familiarizing yourself with the components of each system is crucial to understanding their operation. Although both MBRs and CAS systems aim to treat wastewater effectively, their structural components differ significantly.

Components of Conventional Activated Sludge Systems

- Aeration Tank: The heart of the CAS system, where microorganisms break down pollutants with the aid of aeration.

- Settling Tank (Clarifier): Used for separating treated water from the activated sludge.

- Sludge Recycling: Involves returning a portion of activated sludge to the aeration tank to maintain microbial activity.

Membrane Bioreactor Components

- Bioreactor: Where biological degradation of waste occurs, similar to the aeration tank in CAS.

- Membrane Filtration Unit: Provides solid-liquid separation, capturing suspended solids and allowing only treated water through the membrane.

- Permeate Pump: Drives treated water through the membrane, enabling continuous filtration.

Operational Differences

In your quest to understand the differences between MBRs and CAS systems, acknowledging their operational distinctions is vital. Each technology has unique processes and attributes that influence their functionality.

Energy Requirements

Membrane bioreactors typically require more energy due to the use of permeability pumps and the need to maintain transmembrane pressure. Higher energy demand can be a significant consideration when evaluating operating costs.

Footprint and Space Usage

One of the significant advantages of MBRs is their compact footprint. MBR systems eliminate the need for large settling tanks, making them ideal for areas with limited space. In contrast, CAS systems require larger areas for their clarifiers.

Effluent Quality

MBRs generally yield higher effluent quality due to their superior filtration capabilities. The membranes effectively remove almost all suspended solids, resulting in clearer and more purified water compared to CAS systems.

Advantages and Limitations

Both MBRs and CAS systems come with their own sets of advantages and potential limitations. Understanding these can help you choose the technology that best meets your specific needs.

Advantages of Membrane Bioreactors

- Higher Effluent Quality: Due to the fine filtration by membranes, MBRs produce excellent quality effluent.

- Space Efficiency: MBRs require less space, making them suitable for urban and constrained sites.

- Robustness: MBRs can handle higher load fluctuations due to their superior removal capability.

Limitations of Membrane Bioreactors

- Higher Energy Consumption: The energy needed to maintain transmembrane pressure can be substantial.

- Membrane Fouling: Regular maintenance is necessary to prevent membrane fouling, which can hinder system performance.

Advantages of Conventional Activated Sludge

- Proven Technology: With decades of use, CAS systems are well-understood and trusted.

- Lower Energy Requirements: Generally, less energy-intensive compared to MBRs.

- Cost-Effective for Large Scale: Economies of scale apply, making CAS systems suitable for larger wastewater treatment plants.

Limitations of Conventional Activated Sludge

- Large Footprint: Requires more space due to the settling tanks, which can be a limitation in densely populated areas.

- Variable Effluent Quality: Effluent quality can vary, sometimes requiring additional polishing steps.

Applications in Different Environments

Choosing between MBRs and CAS often depends on the environmental context and specific requirements of the treatment facility. Different applications may favor one technology over the other.

Urban and Space-Restricted Areas

In densely populated urban areas where space is a premium, MBRs offer an ideal solution due to their compact design and high-quality effluent output. They allow wastewater treatment facilities to operate efficiently within limited spaces.

Large-Scale and Conventional Wastewater Plants

Large-scale facilities might benefit more from CAS systems due to their lower operating costs over time and suitability for high-volume applications. These systems work well in regions where space is less of a concern and cost-effectiveness is a priority.

Industrial Wastewater Treatment

MBRs are often preferred for industrial applications where high-quality effluent is necessary, and the space available for treatment facilities is limited. Their ability to treat high-strength waste makes them suitable for various industrial settings.

Maintenance Considerations

An understanding of maintenance requirements is crucial when comparing MBR and CAS systems. Both have different demands and frequencies for maintenance activities.

Maintenance in Membrane Bioreactors

MBRs require regular maintenance to ensure the longevity and efficiency of the membranes. This includes routine cleaning to prevent fouling and periodic inspections.

Maintenance in Conventional Activated Sludge Systems

CAS systems typically involve routine monitoring of sludge characteristics and management to avoid potential issues related to sludge settling and bulking. Maintenance is generally less frequent compared to MBRs but still essential for system performance.

Cost Analysis

Choosing a wastewater treatment system is not only about performance but also about financial viability. Both initial investments and ongoing operational costs are important factors to consider.

Initial Investment

While MBRs might have a higher initial investment due to the cost of membranes and control systems, their space-saving benefits can translate to site development savings.

Operating Costs

Operating costs for MBRs can be higher, mainly due to energy requirements for permeate pumps and potential membrane replacement costs. In contrast, CAS systems tend to have lower energy and operational costs, especially in large-scale applications.

Future Trends in Wastewater Treatment

The future of wastewater treatment involves continuous advancements and innovations. Both MBRs and CAS systems are subject to evolving technologies that enhance their functionality and efficiency.

Innovations in Membrane Technology

Ongoing research is leading to improved membrane materials that reduce fouling and energy consumption, making MBRs even more efficient and cost-effective.

Advancements in Biological Treatment Processes

For CAS systems, advancements in microbiology and process control are helping to optimize sludge characteristics and improve effluent quality while maintaining low operational costs.

Regulatory and Environmental Considerations

Environmental regulations and sustainability goals have an impact on selecting the appropriate treatment technology.

Meeting Stringent Standards

MBRs are well-suited for meeting strict discharge standards due to their superior effluent quality, making them favorable in regions with stringent environmental regulations.

Sustainable Practices

Both MBRs and CAS systems are aligning with sustainable practices by integrating enhanced biological and filtration processes that minimize environmental impacts and improve resource recovery.

Making the Right Choice

Choosing between MBRs and CAS systems involves considering multiple factors, including space availability, effluent quality requirements, costs, and regulatory compliance. The decision often depends on the specific needs and constraints of the project.

Tailoring Solutions to Specific Needs

It’s essential to assess the unique requirements of each treatment scenario, potentially consulting experts in both technologies to find the most suitable solution.

Flexibility and Scalability

Both systems offer opportunities for scalability and flexibility, allowing facilities to adapt to future changes in wastewater treatment demands.

In your exploration of membrane bioreactors and conventional activated sludge systems, understanding these differences provides valuable insights into their applications and potential benefits for different wastewater treatment projects. By weighing the advantages, limitations, and specific needs of your setting, you can confidently choose the best approach for effective and efficient wastewater management.