Have you ever wondered how optimizing process control parameters can enhance the efficiency of activated sludge systems? In the increasingly complex field of wastewater treatment, understanding and managing these parameters are crucial for ensuring effective operation. Activated sludge systems are at the heart of biological wastewater treatment processes, significantly contributing to the treatment by removing organic matter and pollutants.

Understanding Activated Sludge Systems

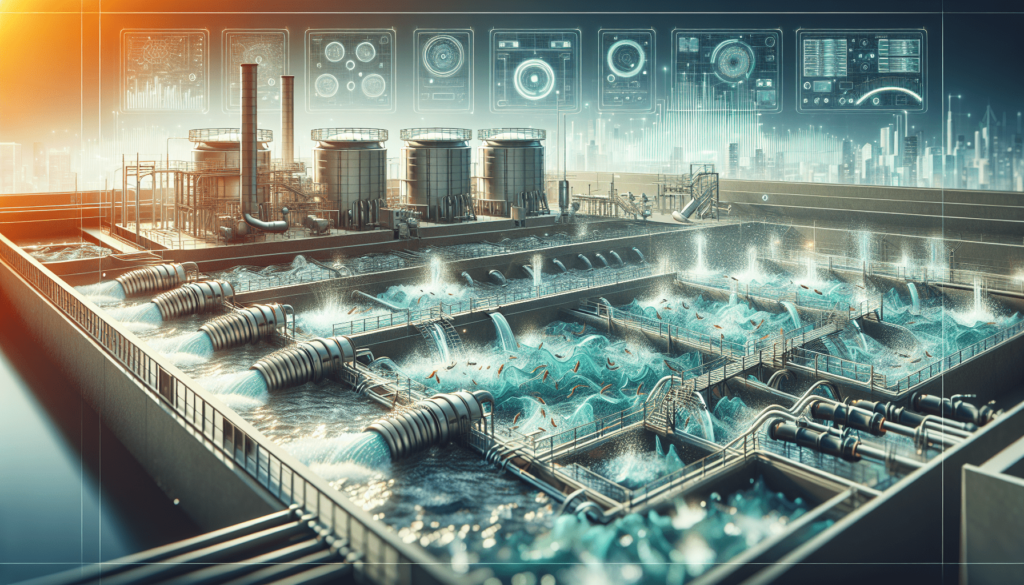

Activated sludge systems are renowned for their ability to treat wastewater efficiently. These systems utilize a mixed culture of microorganisms including bacteria, protozoa, and fungi, suspended in the wastewater to degrade organic matter. Comprehending the basic components of these systems is essential for understanding how to optimize them.

Components of Activated Sludge Systems

The activated sludge process consists of several key components. These include the aeration tank, settling tank or clarifier, and return activated sludge (RAS) system. The operation begins in the aeration tank, where air or oxygen is pumped in to maintain aerobic conditions. The organic contaminants in the wastewater are decomposed by the microorganisms. The settling tank separates the treated water from the sludge, while the RAS system recycles settled microorganisms back into the aeration tank to maintain a high concentration of active biomass.

Importance of Process Control Parameters

Process control parameters play a pivotal role in optimizing the performance of activated sludge systems. They influence the efficiency of wastewater treatment and the stability of the process. By adjusting these parameters, you can ensure the system operates effectively, reducing energy consumption and costs associated with wastewater treatment.

Key Process Control Parameters

Several key parameters govern the activated sludge process. These include sludge retention time (SRT), hydraulic retention time (HRT), dissolved oxygen (DO) levels, mixed liquor suspended solids (MLSS), food to microorganism ratio (F/M), and pH levels. Understanding each is necessary for optimizing system performance.

Sludge Retention Time (SRT)

SRT, also known as mean cell residence time, is the average time the microorganisms remain in the system. It directly impacts the growth and activity of the biomass. Maintaining an appropriate SRT ensures efficient treatment and biomass stability. If SRT is too short, microorganisms may wash out of the system; if too long, the system may become inefficient and consume more energy.

Hydraulic Retention Time (HRT)

HRT is the average time the wastewater spends in the treatment system. It affects the contact time between microorganisms and organic matter, influencing treatment efficiency. Optimizing HRT is critical; a short HRT may lead to insufficient treatment, while a long HRT could result in unnecessary energy use and costs.

Dissolved Oxygen (DO) Levels

Adequate DO levels are crucial for aerobic biological processes in activated sludge systems. Proper aeration ensures that microorganisms efficiently consume organic matter. Monitoring and maintaining optimal DO levels can prevent issues such as excessive energy consumption and inadequate treatment.

| DO Concentration | Impact on System Performance |

|---|---|

| < 1 mg/L | Inadequate aeration, reduced microbial activity |

| 1-2 mg/L | Optimal range for most systems |

| > 2 mg/L | Excessive energy consumption, potential for undesired microbial growth |

Mixed Liquor Suspended Solids (MLSS)

MLSS refers to the concentration of suspended solids in the aeration tank. It reflects the amount of active biomass present in the system. Maintaining an appropriate MLSS level is critical for achieving optimal treatment efficiency and system stability. Both low and high MLSS levels can adversely affect performance.

Food to Microorganism Ratio (F/M)

The F/M ratio denotes the balance between the amount of organic matter and biomass in the system. An optimal F/M ratio ensures microorganisms have enough nutrients to thrive without overloading the system, which could lead to poor treatment and high sludge production.

pH Levels

Maintaining a stable pH is essential for optimizing microorganism activity in activated sludge systems. Extreme pH levels can hinder biological processes and lead to poor treatment outcomes. Most systems operate efficiently within a pH range of 6.5 to 8.0.

Techniques for Optimizing Process Control Parameters

Optimizing process control parameters involves utilizing a combination of operational strategies, advanced technologies, and continuous monitoring. By implementing these techniques, you can effectively enhance the performance and efficiency of activated sludge systems.

Operational Strategies

Operational strategies are fundamental to optimizing process control parameters. These strategies often involve adjusting the operating conditions and parameters based on system performance and wastewater characteristics.

Aeration Control

Aeration is vital for maintaining adequate DO levels and promoting microbial activity. Implementing automated aeration control systems can optimize DO levels, reduce energy use, and enhance treatment efficiency. Techniques such as on-off cycling, variable speed blowers, and feedback control can be utilized.

Sludge Age Management

Effective sludge age management involves regulating SRT to maintain a healthy and efficient biomass. Adjusting sludge wasting rates and RAS flow can help control SRT, ensuring optimal biomass concentration and activity for treatment.

Advanced Technologies

The integration of advanced technologies into activated sludge systems can significantly optimize process control parameters and improve system performance.

Sensor Technology

Installing online sensors for parameters such as DO, pH, and turbidity allows real-time monitoring and control of the treatment process. This technology enables immediate adjustments, preventing deviations from optimal conditions and improving system efficiency.

| Parameter | Typical Sensor Type | Benefits |

|---|---|---|

| DO | Electrochemical | Real-time monitoring, saves energy |

| pH | Glass electrode | Ensures optimal microbial activity |

| Turbidity | Optical sensor | Detects solids concentration |

Supervisory Control and Data Acquisition (SCADA)

SCADA systems provide comprehensive management and control over activated sludge processes. They automate data collection, enable remote monitoring, and facilitate process adjustments. By integrating SCADA, you can optimize process control parameters more effectively.

Continuous Monitoring and Feedback

Engaging in continuous monitoring and feedback is crucial for maintaining optimal conditions in activated sludge systems. This approach allows for early detection of issues and timely adjustments to process control parameters.

Monitoring Tools

Deploying monitoring tools such as online analyzers and sampling devices ensures accurate data collection. These tools help assess system performance, identify deviations, and facilitate proactive adjustments to maintain optimal treatment conditions.

Data Analysis

Analyzing collected data helps identify trends, assess parameter relationships, and evaluate treatment efficiency. By regularly reviewing process data, you can make informed decisions on process adjustments and optimize control parameters more effectively.

Benefits of Optimizing Process Control Parameters

Optimizing process control parameters offers numerous benefits beyond improving treatment efficiency. It enhances system stability, reduces operational costs, mitigates environmental impact, and ensures regulatory compliance.

Enhanced Treatment Efficiency

By maintaining optimal process control parameters, activated sludge systems achieve higher treatment efficiency, resulting in improved removal of organic matter and pollutants. This efficiency ensures compliance with discharge permits and reduces the likelihood of environmental contamination.

Cost Reduction

Optimizing parameters can lead to substantial cost savings. Efficient aeration, for instance, lowers energy consumption, which can reduce operational costs. Additionally, controlled biomass growth minimizes sludge production and disposal costs.

Environmental Benefits

Enhanced system efficiency leads to reduced energy consumption and greenhouse gas emissions, contributing to environmental sustainability. Properly treated effluent minimizes the release of pollutants into natural water bodies, protecting ecosystems and public health.

Regulatory Compliance

Optimized process control ensures consistent compliance with regulatory standards for effluent discharge. Meeting these standards is essential for avoiding fines and maintaining the reputation of your facility as an environmentally responsible operator.

Conclusion

Optimizing process control parameters in activated sludge systems is vital for maximizing their efficiency, sustainability, and operational cost-effectiveness. By understanding and managing parameters such as SRT, HRT, DO levels, MLSS, F/M ratio, and pH, you can significantly enhance treatment performance. Employing strategies such as aeration control, utilizing advanced technologies like sensor technology and SCADA, and ensuring continuous monitoring and feedback will further optimize these systems. Not only does this lead to improved treatment efficiency and reduced costs, but it also positively impacts the environment and ensures regulatory compliance. By adopting these practices, you can ensure your activated sludge system operates at its best, contributing to both environmental protection and operational efficiency.