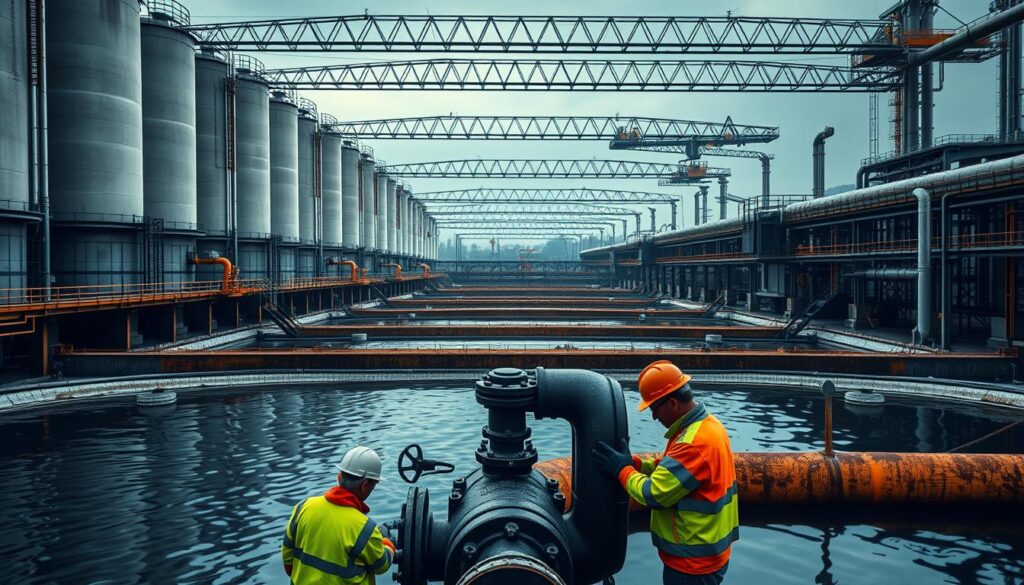

Are inefficient wastewater treatment processes costing municipalities time and resources? Effective wastewater maintenance is crucial for the smooth operation of treatment plants and minimizing environmental impacts.

Efficient maintenance strategies are key to preventing equipment failures, reducing downtime, and ensuring compliance with environmental regulations. This involves implementing a combination of preventive, reactive, and predictive maintenance approaches tailored to the specific needs of wastewater treatment facilities.

By adopting a proactive maintenance strategy, wastewater treatment plants can optimize their operations, reduce costs, and enhance their overall sustainability. This article will explore the different maintenance strategies and their benefits in the context of wastewater management.

Key Takeaways

- Understanding the importance of effective wastewater maintenance.

- Exploring preventive, reactive, and predictive maintenance strategies.

- Learning how to optimize wastewater treatment plant operations.

- Discovering ways to reduce costs and enhance sustainability.

- Implementing proactive maintenance approaches for better compliance.

Understanding Wastewater Systems and Their Maintenance Needs

Understanding the components and challenges of wastewater infrastructure is crucial for maintaining public health and environmental safety. Wastewater systems consist of various components, including pipes, pumps, and treatment plants, which work together to collect, treat, and dispose of wastewater.

Components of Modern Wastewater Infrastructure

Modern wastewater infrastructure is composed of a complex network of pipes, lift stations, and treatment facilities. Pipes are the primary conduits for wastewater, directing it to treatment plants. Pumps and lift stations are critical for overcoming elevation changes and ensuring continuous flow.

Common Challenges in Wastewater System Maintenance

Despite their importance, wastewater systems face numerous challenges. Two significant issues are aging infrastructure and capacity and flow variations.

Aging Infrastructure Issues

Aging infrastructure poses a significant risk, as older pipes and equipment are more prone to failure, leading to potential environmental hazards and costly repairs.

Capacity and Flow Variations

Capacity and flow variations can strain wastewater systems, particularly during heavy rainfall or peak usage periods, potentially resulting in overflows and treatment inefficiencies.

Effective maintenance strategies are essential to mitigate these challenges and ensure the smooth operation of wastewater treatment processes.

The Impact of Proper Maintenance on Wastewater Treatment Efficiency

Proper maintenance plays a significant role in ensuring wastewater treatment plants operate at peak performance. Effective Asset Management and Maintenance Planning are crucial for the longevity and efficiency of these systems.

The importance of maintaining wastewater systems cannot be overstated, as it has far-reaching implications for both the environment and public health.

Environmental Benefits of Well-Maintained Systems

Well-maintained wastewater systems offer numerous environmental benefits, including:

- Reduced pollution in waterways

- Protection of aquatic ecosystems

- Conservation of water resources

By ensuring that wastewater treatment plants are functioning correctly, we can minimize the environmental impact of wastewater discharge.

Cost Implications of Maintenance Neglect

Neglecting maintenance can lead to significant cost implications, including:

- Costly repairs and replacements

- Increased energy consumption

- Potential fines and penalties for non-compliance

Effective maintenance planning can help mitigate these costs by identifying potential issues before they become major problems.

Public Health Considerations

Properly maintained wastewater systems are essential for protecting public health. They prevent the spread of diseases by ensuring that wastewater is treated and disposed of safely.

In conclusion, the impact of proper maintenance on wastewater treatment efficiency is multifaceted, influencing environmental sustainability, cost management, and public health.

Preventive, Reactive, and Predictive Maintenance in Wastewater: An Overview

Understanding the different maintenance techniques is essential for optimizing wastewater treatment processes. The three primary maintenance approaches – preventive, reactive, and predictive – each have their unique advantages and disadvantages.

Defining the Three Maintenance Approaches

Preventive maintenance involves scheduled inspections and repairs to prevent equipment failures. This proactive approach helps in reducing downtime and extending the lifespan of equipment. Reactive maintenance, on the other hand, is performed in response to equipment failure or malfunction. While it is unavoidable at times, relying heavily on reactive maintenance can lead to increased costs and operational disruptions. Predictive maintenance utilizes advanced technologies like sensors and data analytics to predict when equipment is likely to fail, allowing for maintenance to be performed just in time.

Comparative Analysis of Maintenance Strategies

Each maintenance strategy has its place in wastewater management. Preventive maintenance is beneficial for routine upkeep, while predictive maintenance offers the advantage of being proactive without the need for a fixed schedule. Reactive maintenance, though not ideal, is sometimes necessary. A balanced approach that combines these strategies can optimize maintenance operations.

Cost-Benefit Analysis of Different Approaches

The cost-benefit analysis of these maintenance approaches reveals that while preventive and predictive maintenance require upfront investments, they can lead to significant long-term savings by reducing the frequency and impact of equipment failures. Reactive maintenance, though seemingly cost-effective in the short term, can result in higher costs over time due to the potential for extensive damage and downtime.

By understanding and implementing these maintenance techniques effectively, wastewater facilities can enhance their operational efficiency and reduce maintenance costs.

Preventive Maintenance Strategies for Wastewater Systems

Preventive maintenance strategies play a vital role in maintaining the integrity of wastewater infrastructure. By implementing regular inspections, cleaning, and servicing of equipment, wastewater treatment facilities can minimize downtime and ensure system reliability.

Scheduled Inspection Protocols

Regular inspections are crucial for identifying potential issues before they become major problems. Scheduled inspection protocols should include:

- Daily checks on critical equipment

- Weekly inspections of treatment processes

- Monthly reviews of system performance data

Routine Cleaning and Servicing Procedures

Routine cleaning and servicing are essential for maintaining equipment efficiency and preventing failures. This includes tasks such as:

- Cleaning filters and membranes

- Lubricating mechanical components

- Replacing worn-out parts

Documentation and Record-Keeping Best Practices

Accurate documentation and record-keeping are vital for tracking maintenance activities and ensuring compliance with regulatory requirements. Best practices include:

- Maintaining detailed logs of maintenance activities

- Using digital tools for tracking and analyzing maintenance data

Digital Tools for Maintenance Tracking

Digital tools, such as computerized maintenance management systems (CMMS), can significantly enhance maintenance tracking and analysis. These tools allow for:

- Real-time monitoring of equipment performance

- Automated scheduling of maintenance tasks

- Data analysis for identifying trends and potential issues

By implementing these preventive maintenance strategies, wastewater treatment facilities can improve system reliability, reduce downtime, and ensure compliance with regulatory requirements.

Implementing Effective Reactive Maintenance Protocols

In the realm of wastewater management, reactive maintenance plays a vital role in addressing unexpected system failures. This approach involves responding promptly to equipment breakdowns and emergencies, ensuring that wastewater treatment operations continue with minimal disruption.

Emergency Response Planning

A well-structured emergency response plan is crucial for effective reactive maintenance. This plan should outline procedures for identifying, assessing, and responding to equipment failures and other emergencies. It should also include contact information for key personnel and emergency services.

Troubleshooting Common Wastewater System Failures

Troubleshooting is a critical aspect of reactive maintenance, enabling teams to quickly identify and address the root causes of system failures. Common issues include pump failures, pipe blockages, and electrical system malfunctions. By having a systematic approach to troubleshooting, maintenance teams can reduce downtime and restore operations more efficiently.

Minimizing Downtime During Reactive Maintenance

Minimizing downtime is essential during reactive maintenance. This can be achieved by having spare parts and equipment readily available, utilizing mobile repair units, and implementing a 24/7 on-call system for maintenance personnel. Effective communication with stakeholders is also vital to manage expectations and provide updates on the status of repairs.

Resource Allocation During Emergencies

During emergencies, effective resource allocation is critical. This involves mobilizing the necessary personnel, equipment, and materials to the affected site. Prioritizing tasks based on urgency and impact on the system ensures that the most critical issues are addressed first, minimizing the overall impact on wastewater treatment operations.

Predictive Maintenance Technologies in Modern Wastewater Management

Modern wastewater management is increasingly relying on predictive maintenance technologies to optimize system performance. These technologies enable wastewater treatment facilities to proactively address potential issues, reducing downtime and improving overall efficiency.

Sensor-Based Monitoring Systems

Sensor-based monitoring systems are a crucial component of predictive maintenance in wastewater management. These systems utilize advanced sensors to monitor various parameters such as flow rates, pressure, and water quality in real-time. By continuously monitoring these parameters, wastewater facilities can identify potential issues before they become major problems.

For instance, a study by the Environmental Protection Agency (EPA) found that the use of sensor-based monitoring systems can reduce maintenance costs by up to 20% by detecting issues early.

Data Analytics for Failure Prediction

Data analytics plays a vital role in predictive maintenance by analyzing data collected from sensor-based monitoring systems. Advanced data analytics tools can identify patterns and trends that may indicate potential failures or performance degradation. This enables maintenance teams to take proactive measures to prevent failures and optimize system performance.

“The use of data analytics in predictive maintenance has revolutionized the way we manage wastewater systems. By analyzing data from various sources, we can predict potential failures and take corrective action before they occur.” – John Smith, Wastewater Management Expert

IoT Applications in Wastewater Maintenance

The Internet of Things (IoT) is increasingly being applied in wastewater maintenance to enhance predictive maintenance capabilities. IoT devices can monitor equipment and systems remotely, providing real-time data that can be used to predict potential failures.

- Remote monitoring of equipment

- Real-time data analysis

- Predictive maintenance scheduling

Machine Learning for Performance Optimization

Machine learning algorithms can be applied to data collected from IoT devices and sensor-based monitoring systems to optimize system performance. By analyzing historical data and identifying patterns, machine learning models can predict potential failures and recommend maintenance actions.

| Technology | Application | Benefit |

|---|---|---|

| Sensor-Based Monitoring | Real-time monitoring of system parameters | Early detection of potential issues |

| Data Analytics | Analysis of data for failure prediction | Proactive maintenance scheduling |

| IoT Applications | Remote monitoring and real-time data collection | Enhanced predictive maintenance capabilities |

By leveraging these predictive maintenance technologies, wastewater management facilities can improve system reliability, reduce maintenance costs, and enhance overall efficiency.

Regulatory Compliance and Maintenance Requirements

Wastewater treatment facilities must navigate a complex landscape of federal and state regulations to maintain compliance and avoid penalties. Regulatory compliance is a critical aspect of wastewater maintenance, as it ensures the protection of the environment and public health.

Federal and State Regulations Affecting Maintenance

The Environmental Protection Agency (EPA) sets federal standards for wastewater treatment under the Clean Water Act. States may also have their own regulations, which can be more stringent than federal requirements. For instance, some states require more frequent inspections or have stricter effluent standards.

Key Federal Regulations Include:

- Clean Water Act (CWA)

- National Pollutant Discharge Elimination System (NPDES) permits

- Resource Conservation and Recovery Act (RCRA)

Documentation Requirements for Compliance

Maintaining detailed records is essential for demonstrating compliance with regulatory requirements. This includes documentation of maintenance activities, inspection reports, and training records for personnel.

Best practices for documentation include:

- Implementing a centralized record-keeping system

- Ensuring all records are accurate, complete, and up-to-date

- Training staff on documentation requirements

Penalties and Consequences of Non-Compliance

Failure to comply with regulatory requirements can result in significant penalties, including fines and legal action. Non-compliance can also damage a facility’s reputation and lead to loss of public trust.

The following table summarizes the potential consequences of non-compliance:

| Violation Type | Potential Penalty | Additional Consequences |

|---|---|---|

| NPDES permit violations | Fines up to $50,000 per day | Legal action, reputational damage |

| Failure to maintain records | Fines up to $10,000 per day | Increased scrutiny from regulators |

| Non-compliance with state regulations | State-specific fines and penalties | Potential loss of operating permits |

Effective maintenance planning is crucial for ensuring regulatory compliance in wastewater treatment facilities. By understanding the regulatory landscape and maintaining detailed records, facilities can minimize the risk of non-compliance and associated penalties.

Asset Management and Maintenance Planning for Wastewater Facilities

The backbone of a successful wastewater facility lies in its asset management and maintenance planning. Effective asset management ensures that all components of the wastewater system are properly maintained, upgraded, and replaced as needed.

Inventory Management and Equipment Lifecycle Tracking

Inventory management is critical for maintaining an efficient wastewater facility. This involves tracking the lifecycle of equipment and ensuring that necessary spare parts are available. By doing so, facilities can minimize downtime and optimize maintenance schedules.

“Proper inventory management is key to reducing costs and improving the reliability of wastewater treatment operations,” as noted by industry experts. Implementing a robust inventory management system can significantly enhance the overall efficiency of wastewater facilities.

Budgeting for Maintenance Operations

Budgeting is a crucial aspect of maintenance planning. It involves allocating sufficient funds for maintenance activities, including routine servicing, repairs, and upgrades. A well-planned budget ensures that maintenance operations are not hindered by financial constraints.

- Identify maintenance needs

- Allocate funds accordingly

- Monitor and adjust budget as needed

Prioritizing Maintenance Activities

Prioritizing maintenance activities is essential for ensuring that critical components of the wastewater system receive timely attention. This involves assessing the condition and importance of various assets and scheduling maintenance accordingly.

Risk-Based Maintenance Approaches

Risk-based maintenance approaches involve identifying potential risks associated with equipment failure and prioritizing maintenance based on those risks. This proactive strategy can help prevent costly failures and ensure the reliability of wastewater facilities.

By adopting a comprehensive asset management and maintenance planning strategy, wastewater facilities can enhance their operational efficiency, reduce costs, and ensure compliance with regulatory requirements.

Case Studies: Successful Maintenance Strategy Implementations

The effectiveness of various maintenance strategies in wastewater management is best illustrated through real-world case studies. These examples provide valuable insights into successful implementations and their outcomes, helping to inform future maintenance decisions.

Small Community Wastewater System Improvements

A small community in the United States implemented a predictive maintenance program for their wastewater system, resulting in a 25% reduction in maintenance costs over two years. The program included regular equipment monitoring and data analysis to predict potential failures.

Large Municipal Treatment Plant Optimization

A large municipal treatment plant optimized its maintenance strategy by implementing an asset management system. This system allowed for better tracking of equipment lifecycle and maintenance history, leading to a 15% increase in overall equipment effectiveness.

Industrial Wastewater Maintenance Innovations

An industrial facility implemented innovative maintenance technologies, including IoT sensors and data analytics, to improve their wastewater treatment process. This resulted in a 30% reduction in energy consumption and improved regulatory compliance.

Measurable Outcomes and ROI

The following table summarizes the measurable outcomes and return on investment (ROI) for the case studies presented:

| Case Study | Maintenance Strategy | Outcome | ROI |

|---|---|---|---|

| Small Community | Predictive Maintenance | 25% cost reduction | 200% |

| Large Municipal | Asset Management | 15% equipment effectiveness increase | 150% |

| Industrial Facility | Innovative Technologies | 30% energy consumption reduction | 250% |

These case studies demonstrate the potential benefits of implementing effective maintenance strategies in wastewater management, including cost savings, improved efficiency, and enhanced regulatory compliance.

Conclusion: Building a Comprehensive Maintenance Program for Wastewater Systems

Effective wastewater system management relies heavily on a well-structured maintenance program. By integrating preventive, reactive, and predictive maintenance strategies, wastewater treatment facilities can ensure reliability, efficiency, and compliance with regulatory requirements.

A comprehensive maintenance program involves Maintenance Planning, which includes scheduled inspections, routine cleaning, and servicing procedures. Implementing Preventive Maintenance practices helps identify potential issues before they become major problems, reducing downtime and costs associated with repairs.

By adopting a proactive approach to wastewater maintenance, facilities can minimize environmental impacts, protect public health, and optimize treatment processes. As discussed in the previous sections, leveraging technologies such as sensor-based monitoring systems and data analytics can further enhance maintenance efficiency.

Ultimately, a well-designed maintenance program is crucial for the long-term sustainability of wastewater systems. By prioritizing maintenance and embracing innovative strategies, wastewater facilities can ensure they operate effectively and efficiently for years to come.