Have you ever wondered about the precise differences between return activated sludge and waste activated sludge? It’s a topic that’s crucial for anyone involved in wastewater treatment management but can seem a bit daunting with all the technical jargon involved. Let’s break it down in a way that makes sense, clarify why it matters, and how each functions within the wastewater treatment process.

What is Activated Sludge?

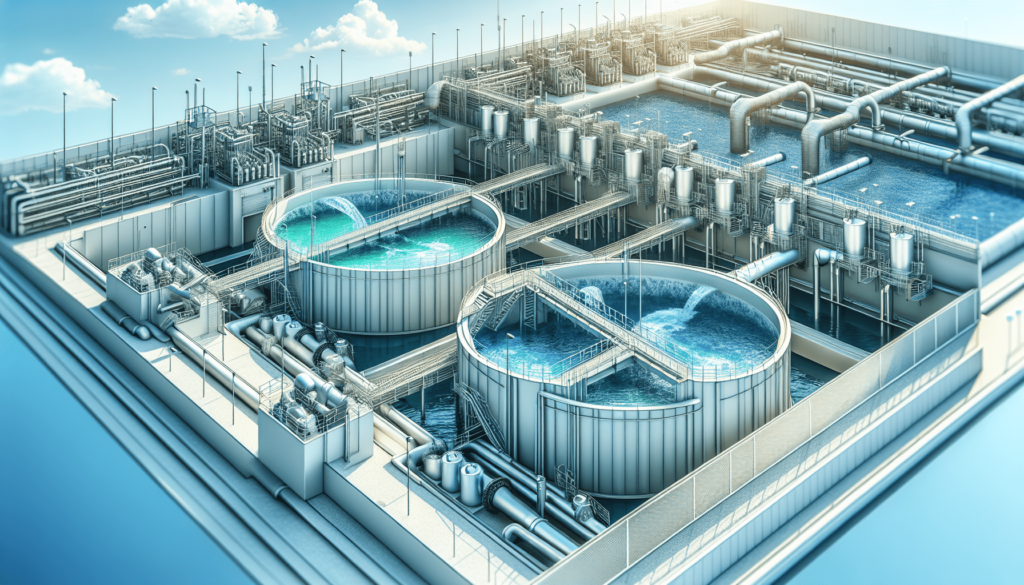

Before jumping into the specifics of return activated sludge (RAS) and waste activated sludge (WAS), it’s essential to understand what activated sludge is in itself. Activated sludge is a mixture of microorganisms and suspended solids used in the treatment of sewage and industrial wastewaters. The process involves aerating the sludge in aeration tanks, promoting the growth of bacteria that digest the organic matter present in wastewater. This method is highly effective and widely used worldwide for enhancing water quality.

The Role of Microorganisms in the Activated Sludge Process

Microorganisms play a pivotal role in the activated sludge process. Imagine them as tiny, hardworking creatures feasting on the organic material in sewage. These organisms help break down waste, converting it into cleaner effluent. They thrive in an aerated environment where oxygen is plentiful. The type and health of these microorganisms largely determine the success of the activated sludge process.

Understanding Return Activated Sludge (RAS)

What is Return Activated Sludge?

Return activated sludge, commonly abbreviated as RAS, refers to the recycled portion of settled sludge that is returned from the secondary clarifier to the aeration basin. The primary function of RAS is to maintain an optimal concentration of microorganisms within the aeration tank, ensuring efficient treatment.

Why is RAS Important?

RAS is critical because it helps maintain a stable microbial population needed to treat the incoming wastewater effectively. Without the continuous return of active microorganisms, the treatment process could become inefficient or fail altogether.

How is RAS Utilized in Treatment Plants?

The process of recycling RAS involves diverting it from the settling tanks back into the aeration tanks. By doing this, treatment plants ensure an adequate supply of microorganisms. This recycling process is a pivotal component in maintaining balance in the tank’s biologic mixture. The levels of RAS returned and the proportion of new sludge added must be carefully controlled to optimize the treatment process.

Unpacking Waste Activated Sludge (WAS)

What is Waste Activated Sludge?

Waste activated sludge, or WAS, is the excess portion of sludge that is removed from the system to prevent an overaccumulation of microorganisms and solids. While RAS is recycled back into the system, WAS is taken out to maintain system balance.

Why Must WAS be Removed?

Removing WAS is essential to prevent biomass from exceeding the handling capacity of the system. Once the microorganisms have processed enough material, continued growth can lead to inefficiencies and potential environmental discharges if the sludge volume becomes too great. Regular removal of WAS ensures the treatment system stays efficient and compliant with regulatory discharge limits.

How is WAS Handled Post-Process?

After being removed from the treatment system, WAS undergoes further processing. This often involves thickening, digesting, dewatering, and sometimes even incineration or composting, depending on the treatment facility’s setup and local regulations. This step is crucial for safe disposal or reuse of the byproduct.

Key Differences Between RAS and WAS

Understanding the differences between RAS and WAS requires acknowledging their roles within the treatment plant:

| Aspect | Return Activated Sludge (RAS) | Waste Activated Sludge (WAS) |

|---|---|---|

| Purpose | Recycles microorganisms to maintain treatment efficiency | Removes excess microorganisms to prevent overloading |

| What happens to it? | Returned to aeration basin | Removed from the system |

| Impact on process | Keeps microbial activity balanced | Prevents excess biomass accumulation |

| Disposal | Not typically disposed; continuously cycled | Disposed of after processing |

Why Understanding RAS and WAS is Important for Water Treatment

Understanding the distinct roles of RAS and WAS helps ensure the smooth operation of wastewater treatment facilities. When properly managed, RAS keeps the biological population at an optimal level, while WAS management prevents accumulation and supports regulatory compliance. Mismanagement of either can lead to treatment inefficiencies or regulatory challenges.

Common Misconceptions About RAS and WAS

There are several misconceptions when it comes to RAS and WAS. For instance, one may think they are interchangeable, but their functions in the wastewater treatment process are very distinct. RAS is integral for maintaining the microbial population, while WAS ensures an overflowing population doesn’t reduce system efficiency. Understanding these distinctions prevents costly mistakes and system failures.

Steps to Optimize RAS and WAS in Treatment Plants

Assess Your System Regularly

Regular monitoring of system performance helps determine the necessary RAS and WAS levels. Parameters such as sludge volume index, mixed liquor suspended solids, and effluent quality should be frequently checked.

Adjust Flow Rates Based on Demand

Flow rates of RAS and WAS can be adjusted based on system load and wastewater characteristics. Ensuring proper flow can drastically improve operational efficiency.

Implement Advanced Control Systems

Using advanced control systems and sensors can help automate adjustments to RAS and WAS flows, ensuring the system remains balanced and efficient.

Challenges in Managing RAS and WAS

Managing RAS and WAS is not without challenges. Factors like influent variability, temperature changes, and equipment failures all pose risks to maintaining the delicate balance needed for efficient wastewater treatment. Skilled operators and robust monitoring systems can mitigate these challenges.

Troubleshooting Common Issues with RAS and WAS

Problems such as excessive foaming, rising sludge, or poor effluent quality often point to issues with RAS and WAS management. Identifying the root cause—whether it’s over-recycling RAS or inadequate WAS removal—can usually be addressed with adjustments to flows and volumes.

Future Trends in Activated Sludge Management

Advancements in technology continue to impact how RAS and WAS are managed within treatment plants. Innovations such as real-time monitoring, machine learning algorithms, and predictive maintenance are enhancing the ability to optimize sludge handling processes for increased efficiency and compliance.

Summary

Grasping the concepts of return activated sludge and waste activated sludge is essential for anyone involved in wastewater treatment. Each plays a distinct role, with RAS maintaining the bacterial population for continued treatment and WAS preventing system overload by removing excess material. With careful management, the processes work harmoniously to keep our water clean and safe.

In the end, whether you work in a treatment facility or are simply curious about where our water goes after it swirls down the drain, understanding the underpinning processes of RAS and WAS helps illuminate a crucial aspect of environmental stewardship. Equipped with this knowledge, you’re now better prepared to comprehend the intricacies of wastewater treatment and its vital role in our ecological health.